Accuride Reduces $1.5 Million in Freight Spend Annually

Transforming ocean freight operations with Pando's AI-powered solutions, Accuride gained visibility and control during global supply chain disruptions.

$1.5 Million

annual cost savings through streamlined freight audit

100 %

Digital documentation and audit compliance achieved

20 %

Reduction in accessorial freight charges

Challenge vs Outcome

Business challenges

- 100+ containers lost in ports during supply crisis.

- Manual documentation causing critical shipment delays.

- $2 million in unnecessary accessorial fees paid.

- Siloed systems across multiple logistics partners.

- Invoices paid without proper verification processes

Business outcomes

- 100% vessel tracking for all import shipments.

- 100% digital documentation management achieved.

- $300-500 savings per container on accessorial charges.

- Unified platform for 3000+ global shipments annually.

- Automated invoice reconciliation against contracted rates.

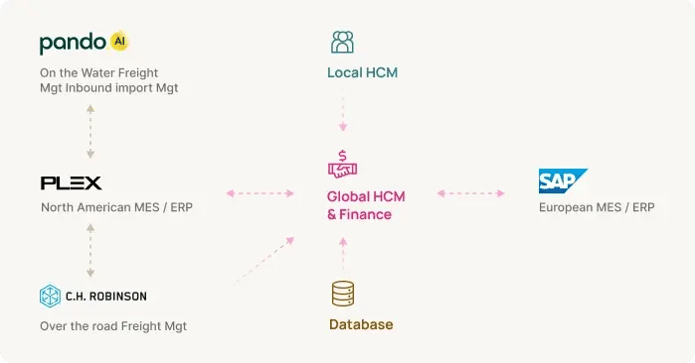

Accuride Corporation is a leading manufacturer of wheels and wheel-end components for the global commercial vehicle market with $1.3 billion annual revenue. Accuride operates a complex international supply chain with 14 manufacturing facilities, 4000+ employees across North America, Europe, and Asia, and global shipments of 3000+ containers annually.

Industry

Automotive

Region

North America

Solutions used:

- AI transportation expert

- AI freight audit & pay specialist

Lost containers and spiralling costs during supply chaos

When Accuride's SVP of Global Supply Chain joined the company in late 2021, she walked into a perfect storm of supply chain disruptions. Accuride's logistics operations were in crisis with a ship stuck in the Suez Canal, record port congestion, container shortages, and a driver shortage. Over 100 containers were lost in the system, with no visibility into their location or status.

Customer calls demanding product were escalating daily, but the logistics team had no answers. Information was scattered across Excel spreadsheets, emails, and disjointed systems from various 3PLs and brokers. Documentation was entirely manual, causing critical delays in customs clearance and delivery.

Most alarming was the financial impact. Without visibility or control, Accuride racked up over $2 million in accessorial fees like detention and demurrage. Payment processes were equally chaotic – invoices were being paid without proper verification, with 72 different categories of charges flowing in from multiple sources for a single container.

We had no way to fight that. We had to pick up our product. So that was my first month in the new job, racking up over $2,000,000 in accessorial fees.

- Skotti Fietsam, SVP of Global Supply Chain

The siloed approach meant that freight forwarders, carriers, customs brokers, and internal teams were all working in separate systems, making coordination nearly impossible. Without a unified platform, shipment planning was reactive rather than strategic, and carrier selection was based on geography rather than performance or cost.

A lot of our processes before were very manual and now with PANDO it has freed up some of our time so we can focus on the important day to day responsibilities.

- Brian C, Logistics Coordinator

Saving $1.5 million annually while gaining complete visibility

Real-time tracking transforms ocean freight visibility

Pando's solution provided Accuride with comprehensive GPS-enabled tracking for every container crossing the ocean. The visual map interface displays all active shipments with real-time location updates and milestone tracking. This visibility extends across booking confirmation, document transfers, and arrival notices, enabling proactive management of shipments at every stage. Accuride can now instantly locate any container and anticipate potential delays before they impact operations.

With Pando we can show them on a map exactly where the container is at any given moment.

- Jacob Wirick, Logistics Specialist

Digital documentation eliminates shipment delays

The digital document management system built within Pando revolutionized how Accuride handles shipping documentation across partners. Smart workflows automatically trigger document requirements and track completion status, while built-in compliance checks validate accuracy. The platform's collaborative features enable real-time document sharing, eliminating version control issues and reducing documentation-related delays that previously plagued their operations.

The system is very easy to navigate and has given us much more visibility on the Logistics side.

- Brian C, Logistics Coordinator

Automated alerts prevent costly detention charges

Pando's proactive alert system identifies potential problems before they generate costs. The system flags containers approaching detention or demurrage thresholds, automatically notifying stakeholders when action is needed. This predictive capability allows Accuride to prioritize critical shipments based on financial impact rather than just timing, dramatically reducing the accessorial fees that had previously cost them millions.

The freight audit and pay module has been a revolutionary change for our organization.

- Justin Scull, Logistics Manager

Streamlined audit process recaptures lost revenue

Pando's automated invoice reconciliation compares carrier charges against contracted rates, eliminating overpayments. Accuride reduced chargeable categories from 72 to just 7, with defined acceptance parameters for each. The system flags discrepancies instantly, allowing Accuride to dispute incorrect charges before payment rather than after the fact.

This has generated significant cost savings as we can now reject invoices where we were billed incorrectly and send back to the provider to send the revised invoice with the correct charges.

- Jacob Wirick, Logistics Specialist

Data-driven carrier selection optimizes spend

The rate manager within Pando transformed how Accuride selects carriers and routes shipments. Rather than geographic assignments, the platform presents all available options with associated costs and transit times for each shipment. This performance-based selection process drives competition among carriers and ensures Accuride always gets the best value rather than defaulting to historical relationships.

Invoice Audits are very valuable for us as they help us to get a very granular view of our total logistics spend

- Justin Scull, Logistics Manager

Integrated platform strengthens crisis management

Pando's unified platform connects all stakeholders in Accuride's supply chain, enabling seamless collaboration during disruptions. When the Baltimore bridge collapsed, Accuride immediately identified affected shipments and rerouted them within hours, demonstrating the system's power during crises. This integrated approach ensures continuity despite unexpected disruptions that would previously have caused extended delays.

The Pando team has been great and has expressed an ongoing commitment to our success in implementation.

- Justin Scull, Logistics Manager

Accuride's transformation from logistics chaos to controlled excellence illustrates the power of digitization in the freight management space. By implementing Pando's AI-powered TMS and Freight Audit & Pay solutions, Accuride not only gained complete visibility into their global shipments but also achieved dramatic cost savings through improved processes and financial controls.

The results speak for themselves: $1.5 million in annual cost savings, $300-500 reduced cost per container, 100% digital documentation compliance, and complete ocean freight visibility. Beyond the metrics, Accuride has fundamentally changed how they operate, moving from reactive crisis management to proactive, data-driven logistics.

As Accuride looks to the future, they plan to expand their Pando implementation to include their European operations, integrating their SAP system to achieve truly global visibility and control. The successful partnership between Accuride and Pando demonstrates how the right technology partner can transform logistics from a cost center to a strategic advantage.

The reporting capabilities that we have access to now with Pando are much better than anything we had before.

- Brian C, Logistics Coordinator